Eco-design manufacturing

Ecodesign at the heart of Re-uz ® practices

Eco-design is a design approach that takes environmental concerns into account throughout a product’s lifecycle, starting from the earliest stages of development.

For Re-uz ®, eco-design at the heart of all our practices. Our products are the result of thorough consideration that integrates aesthetics, durability, as well as practicality and safety for both professionals and consumers. Every cup, dish, mug and plate we design embodies our commitment to creating solutions that fit into a circular system and respect natural balances.

Ecodesign, cornerstone of a circular model

A crucial approach for a product’s sustainability, eco-design is based on a forward-thinking vision. It involves anticipating and considering environmental needs even before the product comes into existence.

At Re-uz®, this means planning the production of containers with a particular focus on their impact. This includes choosing sustainable materials to ensure the longevity of the containers, using single-material manufacturing to guarantee recyclability, and creating timeless designs that remain relevant over the years. The goal is to create highly durable items, maximise their use, and optimise their end-of-life.

Our design teams, based in Europe, have integrated these principles into the creation of each container…

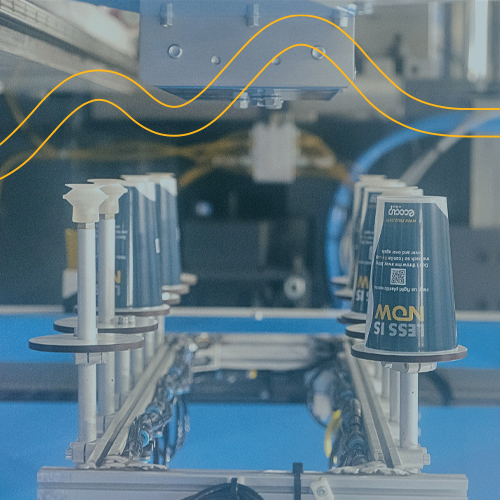

Injection moulding: A sustainable manufacturing method that minimises impact

For manufacturing Re-uz® cups, we use injection moulding, an efficient process for creating lightweight and durable containers while minimising waste. Polypropylene pellets are heated and injected directly into moulds, allowing for precise material use and reduced losses. Any excess material is easily reintegrated into the production process as recycled material, contributing to sustainable resource management.

Injection moulding also allows for the production of cups in a single piece. The continuous structure of the glasses provides increased strength. This monobloc manufacturing ensures better resistance to impacts and breakage, thus enhancing durability.

Customising cups: Techniques that support eco-design

Customisation of cups, through techniques like screen printing, IML, or digital printing, fully supports our eco-design approach. It adds character to the cups, encouraging their reuse.

IML, which integrates labels directly during moulding, reduces label waste and enhances the recyclability of products. Ideal for large runs, screen printing optimises ink usage while limiting waste, allowing for the customisation of many cups with a reduced impact. Digital printing, on the other hand, offers great flexibility by enabling on-demand customisation, which avoids overproduction and reduces material waste.

Each customisation technique is designed to maximise the durability of the cups, aligning with our commitment to a comprehensive approach to eco-design.