X

- No products in the list

Re-uz.com

Re-uz.com

Re-uz.com

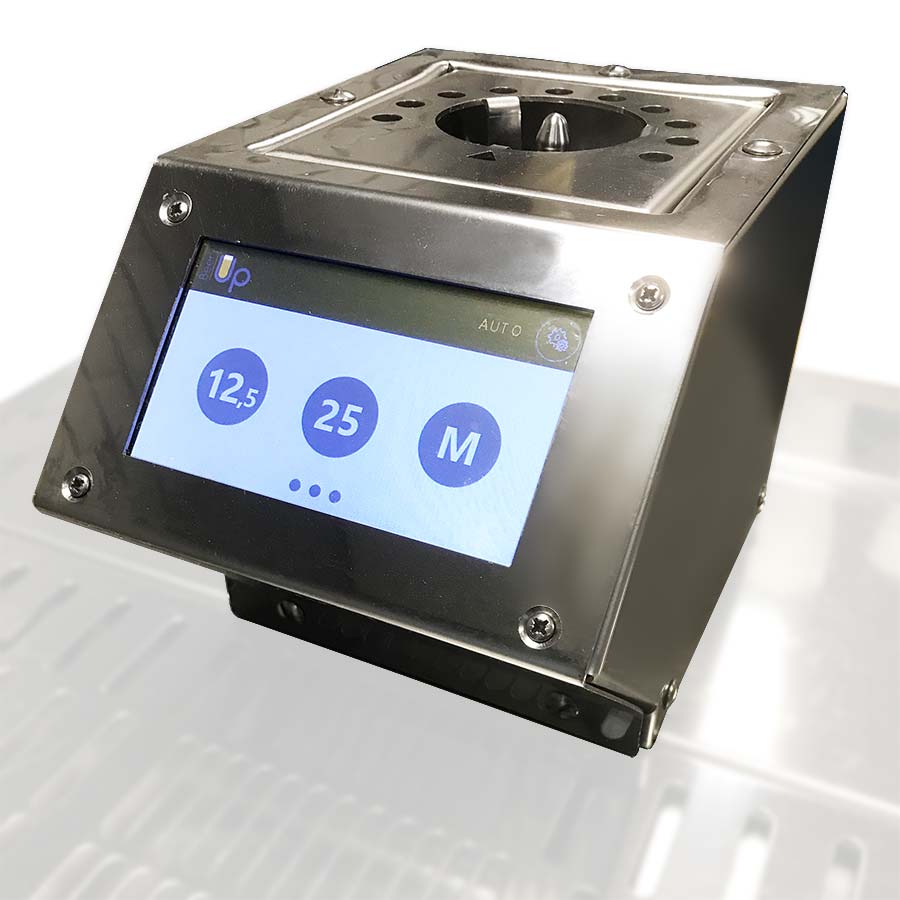

Beer Up’s Box Up allows you to control and adjust the draft via a touch-sensitive LCD screen. The Box Up is installed like a column, connecting to the existing refrigeration system. It can then be used either in self-service mode, or by staff.

| Nombre de lavage | 150 (according to our testing protocol) |

| Reference | L02491BU |

| Availability | purchase |

| Container Compatibility | Beer Up glasses / tumblers |

| Draw | single draw |

| Filling | automatic, manual, removable spout |

| Beer pressure service | 25 cl Beer Up, 50 cl pint Beer Up, bottom filling |

| Draw grid | choice of upstream draw: 25 cl or 50 cl via specific grid, Interchangeable grids during service |

| Set of grids provided | 1 grid for 25 cl draw, 1 grid for 50 cl draw |

| Service | bar service |

| Filling control | Touch screen |

| Distribution system | on existing installation, via CO2 bottle (not supplied) |

| Speed | volumetric meter |

| Lighting | LED lighting when filling, screen backlight |

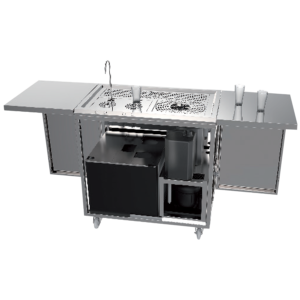

The Beer Up Box Up device offers a unique unprecedented service!

Controlled by a touch screen, the device can be implemented on an existing standard print run. This system optimizes and facilitates counter service.

Easy to install, this draught head adapts to standard connections (kegs and CO2 cylinders), making serving draught beer child’s play.

Beer Up System’s Box Up device makes serving draught beers easy. No need to be a printing expert. There’s no need to master glass tilting to avoid overflow and excessive foaming…

How does glass filling work? Simply place the cup in the center of the grid ( orifice ), then select the serving method ( manual or automatic ) … Box Up does the rest!

How can a glass be filled from the bottom? When the glass is clicked into place, a filling nozzle is inserted into the Beer Up cup. Each cup has a hermetically sealed valve at the bottom. The nozzle starts the filling process with a spiral jet that generates a light foam. Filling stops automatically once the glass has been filled to a perfect foam neck.

Beer Up System’s Box Up filler is combined with dedicated bottom-pressure cups.

Beer Up cups are eco-designed and reusable. Made of plastic, they are sturdy and unbreakable. Their curved shape makes them easy to hold and a real pleasure to eat.

50 cl Beer Up pint or 25 cl Beer Up half-pint: forget potential breakage and broken glasses.

All Re-uz ® containers are 100% recyclable. Made from a single plastic material (walls and valve), they can be easily recycled.

Bottom-filling and the resulting automation optimize service efficiency while preserving the quality and authentic flavor of draught beer .

Beer Up System ensures that every centilitre in the keg is served. Thanks to this device, there’s no need for a starter. It is estimated that 10-15% of barrels are thus “not wasted”.

Beer Up System’s Box Up filler has compact dimensions: 20.2 cm wide, 13.7 cm deep and 14 cm high.

The control screen makes it easy to use (even in the dark or subdued light of a building). When filling, an LED backlight activates and illuminates the glass.

The volumetric counter provides an accurate record of the volume of beverages served.

The Box Up filler has an interchangeable grid for 25 cl or 50 cl prints. The grid is installed before the service, but can be changed at a moment’s notice.

Offer your customers a unique experience! Beer Up returnable cups can be customized to your image. They’ll shine on tables and enhance your brand. They’ll captivate your customers and convey the values of re-use and innovation.